Blair PAtrick

445″ 390-based stroker with out of the box BBM heads. No porting was done at all.

591 HP, 587 TQ with stock heads out of 445″ on 93 pump gas.

FE POWER FORUM:

445″ with BBM as cast stock heads. 591HP/587TQ

Standard 482″ FE with BBM cast iron block and near stock BBM heads. These heads received very minor hand blending immediately under the valve seat, no porting work at all and no blending past the immediate valve seat area.

666 HP and 636 TQ with near stock heads out of 482 cu. in. (on pump gas!)

FE POWER FORUM:

482″ with near stock as cast BBM heads – 666HP/636TQ

The engine had a .700 lift solid roller cam, and 14.5 to 1 compression ratio.

October 4, 2014

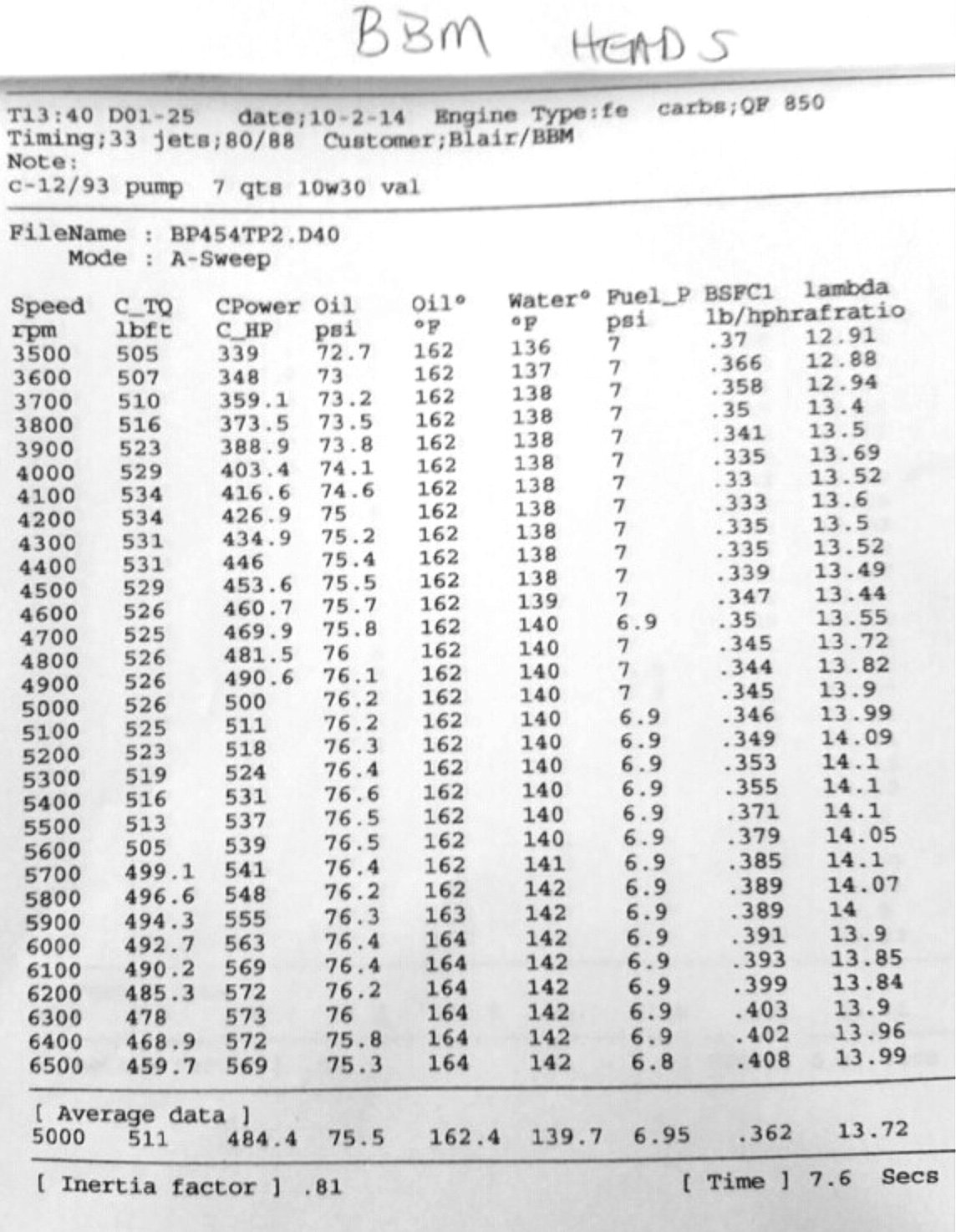

I had the “head comparo” 390’s on the dyno the last couple of days. I thought both went well. As far as I know, this was also the first testing of the BBM cylinder heads.

I’ll go into some more detail later……..pretty tired at the moment, but I wanted to post some of the info for those who are interested. Both of these engines are loaded with good parts,

but they are “real” 390’s with C7AE-B rods (properly prepped) and iron 390 cranks, stuffed in general production C7 390 blocks.

We ran the 390 CJ (iron N Cobra Jet heads) first. I knew right where to go with this one pretty quick. Beating on the 390 Stocker engines for years had us in very familiar territory.

I knew a good baseline jet, and exactly where to go on the timing. We put ten pulls on this one. After it sealed up and repeated well, we picked around at the jets a little, and sneaked up on an rpm range to settle on for the comparison. The limited travel hydraulic rollers, conical springs, and NON ADJUSTABLE factory rockers all did exactly what I hoped they would. The CJ headed 390 made it’s way to 6500 rpm with no hint of valve float (more on this later!) I cammed the engines for what I thought would be a 62-6300 peak, just because I wasn’t sure how far the combo would go before float. I pulled it from 3500 to 6500 on the money runs. At 3500, she made 318 hp and 474 tq. By 4600, it made peak torque of 504 lb/ft. At 6000, she made 517 peak power.

Very flat curves……509 at 5800 and still had 509 at 6500 where we shut it down. I get the hint it would hold it’s head up well, probably to 7000 before it falls off the cliff, but I needed to move on to the BBM engine.

I was HAPPY with the 517 power and 504 torque out of a 10:1 engine at 396 cubes.

Up next was the BBM’er. I took an educated guess at where to start with on the timing. I talked myself into 35 degrees for a baseline. We sealed it up, and then went to work. As the stroke changes, timing requirements change also, but at the 3.78 stroke, after going both ways to verify it, the chamber wanted 33 total. I ran a 50/50 mix of C12 and 93 pump gas, mainly because I didn’t want to detonate the engine while exploring the timing requirements. Both engines got the same carb and the same gas. I was happy happy with only needing 33 degrees!

There is power there by not working the engine against itself. The CJ had to have 41 total for the best numbers. We eased into the power pulls to get a hint of the fuel curve. It took six jet numbers more than the CJ. I am sure this is due to the bigger volume in the heads killing the signal a little, and also the super exhaust port scavenging on overlap. After some incremental changes, we were six jet numbers higher to get the same A/F numbers. The heads performed with no issues. At 3500, this honey made 342 hp and 510 tq. Peak torque came out at 535 lb/ft at 4100 rpm. Peak power was 574 at 6200 rpm, and stayed there to 6500. I was surprised to see that power! To me, that is VERY good for a 10:1 engine at 396 cubes.

I had to pull it to 7000 just to see if my valvetrain experiment would do it. We pulled it to 7000 with NO issues. Power was still at 541, but heading south by then. I think the BBM head is a hit, and I also think the limited travel lifters with the non-adjustables did well to go to 7K without float.

We’ll go deeper as the thread goes, but I is tired!

-Blair Patrick

Dueling 390’s Dyno Data

September 12, 2014

I made a post the other day about testing two pretty much identical 390’s. One will get iron CJ heads, and the other a set of BBM castings. We finished the CJ engine this week, and I also finished the BBM heads for the other one. I wanted to be sure that I gave the iron heads a fair shake, and I actually may have favored them a bit, in terms of time spent. Flow numbers on both to follow. I used the same valvejob on both, and the same “bowl blend”, but I did spend a little more time massaging the short turn on the CJ’s. Neither head is what I would call ported,

there is no work on the BBM heads more than 1/2″ either side of the seat ring. A little blending in the port, and a little blending in the chamber. No porting or polishing of the port past that.

The CJ head came in with 156 cc’s on the intake runner. I am going to cc the BBM tomorrow just for the sake of information. The identical cams checked at .584 lift in the CJ, and .572 in the BBM head. Same cam, same block, but likely just a little different geometry somewhere. I see that quite a bit just swapping between heads………the lift can vary.

Here are the flow numbers on both. The BBM has a 2.2 intake, the CJ a 2.09. Both have the same size 1.65 exhaust valve.

Intake flow CJ BBM:

.100 97 92

.200 181 157

.300 226 215

.400 250 254

.500 261 283

.600 266 292

.700 268 295

.800 266 300

Exhaust flow CJ BBM:

.100 60 76

.200 116 124

.300 151 165

.400 170 190

.500 181 212

.600 186 224

.700 190 231

.800 192 236

Another point of interest is the comparison of the cost to get there with both. I figured the CJ head castings at a $600 value bare, and the BBM’s at $1350 bare to start with.

The BBM prep was normal for new castings. The CJ’s, a typical pair of 8K dated castings, needed surfaced on all three faces, two broken exhaust bolts to take out, intake and exhaust seats, new guides, a pressure test, and a bake-and-blast, in order to get to a similar starting point as the new heads. The valve cost is the same. If I priced the heads only, prepped as they are,

with no springs, retainers, cups, or locks, the iron heads would come in at $2180, and the BBM’s at $2150. The prices are for the sake of comparison here……not intended as a sales ad.

The amount of refurb required on the old castings drives the price up to a point that is basically the same to get to the same finished product in terms of quality. You can see the flow numbers, and in the next couple of weeks, we will see what that converts to in terms of dyno power and torque. I didn’t plan to end up at basically the same “cost” on both……it just shook out that way. There is no way to get the CJ’s that good without porting them unless they got new seats, which gave me the material to get my seat work like I wanted.

Point being, yes…..a person could do the iron heads cheaper, but they would not come out that good. I thought the cost would be relevant to the discussion, so I added that info.

Both engines will get hydraulic rollers, Morel severe duty lifters, and conical valve springs. I hope I can get them to make it to 6500 rpm without floating the valves. The springs weigh 75 grams with the retainer, compared to 135 for a traditional dual spring, even using a lightweight tool steel retainer on the dual spring. The Ford non-adjustable rockers also have less mass moment inertia than a rocker with an adjuster and a roller tip hanging on either end. If it goes like I think it may, we should get 2-300 more rpm out of the combo.

Most HR’s usually peter out at 6000 to 6200, so we will see.

Take a stab at it Werby…..both are 396 cubes, and 10:1 static. 240/248 @ .050 on a 110. Perf RPM’s, QF annular 850 carbs.

-Blair Patrick

September 7, 2014

There was a post the other day about a “head shoutout”. This isn’t exactly a shoutout, but it is a good A-B comparison. We did two equally prepped 390 shortblocks. Both have the same hydraulic roller grind. .570 at the valve, through Ford non-adj rockers on good shafts. Both are 240/248 @ .050, on a 110. Both will have Perf RPM manifolds with the same light port-match job.

One engine will get 10:1 C/R and BBM heads. The other will get 10:1 and iron Cobra Jet N heads. Both will have the same amount of time and effort spent, and the same valvejob. The BBM’s get 2.200/1.65 valves, and the CJ’s get 2.09/1.66. Basically standard issue for both, plus I didn’t want to use up CJ heads that did not need bigger valves by going 2.200 on those. Both will get a blending job and a little massage work on both sides of the seats, but NO “porting” on either one. I worked the short turn on the CJ’s a little more, since I didn’t give them bigger valves. When we get the dyno numbers, back to back, with the same carb on both, I will post all the info, as well as the head flow numbers on both.

I do know that the BBM heads will probably be 40 cfm better at .500, based on what I have seen already, but I will have to flow them both before they are bolted on the engines. Both will get 850 annular QF carbs, but I will compare them with the same carb for the sake of the test. It will be fun and interesting to see what we find, and also good info for all on the Forum.

Both engines belong to the shop, but they will both go in the classifieds when they come off the dyno!

-Blair Patrick